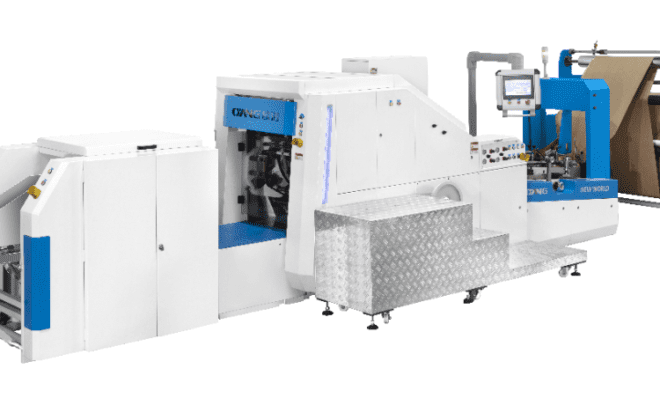

Hot stamping machine Guowang C106 Y

1.Taiwan feeder with 4 suction cups for lifting & 4 suction cups for transfering ensures stable and fast paper feeding.

2.Preload device, non-stop feeding function, with Max pile height up to 1400 mm.

3.Rail-guided preload device enables operators to move the prepared pile to the feeder accurately and conveniently.

4.Side layers can be shifted from pull layers to push layers to fit different formats.

5.Side and front layers are equipped with precise location aligning photocells with adjustable sensitivity.

6.Paper feeding will slow down when the paper is about to reach front lays to achieve a more accurate paper orientation.

7.German stainless steel brings you a smooth and quick paper conveyance.

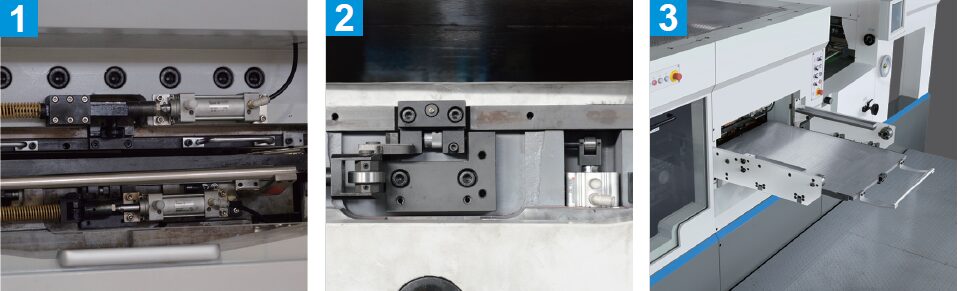

1.Synchronous longitudinal & transversal foil feeding enables foil stamping at both direction, which reduces foil using and shorten replacing time.

2.Optional longitudinal axles can reach to 6 at most, which are controlled by Japan Yaskawa servomotor.

3.Operator-friendly retractable foil holders are suitable for foil with maximum diameter 250mm.

4.Both longitudinal & transversal blowers for paper stripping are available for facilitating big format foil stamping.

5.Human–computer interaction screen ensures a quick setting of foil feeding interval.

6.The machine alarms when the foil is shorter than 6 meters and the diplay shows the foil length left.

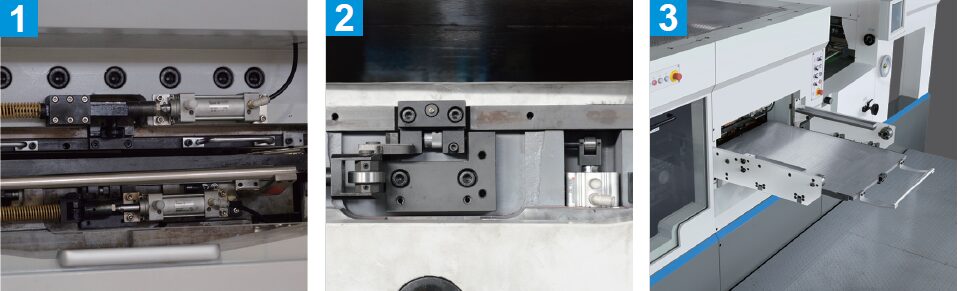

7.Cutting force is controlled by Japan Fuji servo motor to achieve accurate and stable die cutting controlling through touch screen. The cutting force adjustment is accurate to 0.01mm.

8.The chase and die cutting plate are automatically locked by SMC pneumatic cylinder; comparing to manual locking, this ensures much faster and sfter operation.

9.Centerline registering installation system of the chase ensures a convenient and fast assembly of cutting die.

10.By using special auxiliary tools, cutting dies of different sizes can be adopted to meet different task needs.

11.Grippers are structured in an adjustable type to ensure accurate paper registering.

1. Alternating current motor controlled delivery brake helps collect and align the paper.

2.You can also control each unit of the machine by using the 10.4’ touch screen at delivery unit.

3.Auxiliary delivery rack ensures non-stop delivery;

4.Servomotor controlled rear layers are applicable for paper with different sizes.

5.Synchronous belt is wear resistant and of long service life.

| Machine parameter | |||||

| Sheet size | 1060*760mm (MAX.) | ||||

| 450*670mm (MIN.) | |||||

| Max.die cutting size | 1045*745mm | ||||

| Max. stamping size | 1020*740mm | ||||

| Gripper margin | 7-17mm | ||||

| Max.die cutting force | 300 TON | ||||

| Paper size | GSM Card Board:90~2000g/m2 | ||||

| Corrugated Paper:≤4mm;Paperboard:0.1-3mm | |||||

| Max. die-cutting speed | 7500 SHEET/HOUR | ||||

| Max. stamping speed | 6500 SHEETS/HOUR | ||||

| Max. hologram stamping speed | 5500 SHEETS/HOUR | ||||

| Heating zone | 20 heating zones, temperature 20°-200° | ||||

| Max. pile height at feeder | 1600mm | ||||

| Max. pile height at delivery | 1350mm | ||||

| Main motor power | 11kw | ||||

| Total power | 46kw | ||||

| Weight | 19 TON | ||||

| Overall dimension | 6260*4560*2580mm | ||||

| Max. longitudinal foil diameter | Φ250mm | ||||

| Air source | 0.5~0.8MPa;600L/min | ||||