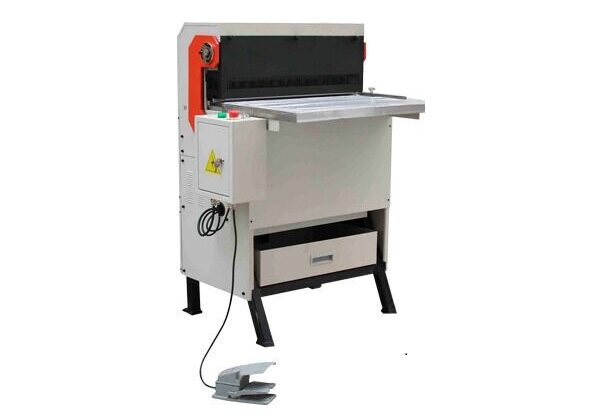

LZ1227B INLINE BOTTOM FOLDER GLUER

Rigidity of whole machine is strengthened,machine is durable in use;

Adapts to a wider range of cardboard and can process narrower and smaller cardboard;

High degree of automation,PLC program control,quick to change order.

|

Machine model

|

LZ920B

|

LZ1227B

|

|

|

Max. speed

|

200m/min

|

||

|

Cardboard type

|

Suitable for A, B, C, AB, AC etc. 3-5 ply corrugated cardboard

|

||

|

Cardboard thickness

|

2-8mm

|

||

|

Suitable cardboard

|

Min. size

|

260×720

|

260×720

|

|

Max. size

|

900×2040

|

1200×2740

|

|

|

Size scope

|

W:170-700

L :170-700

W + L:340-1000

G:≤40

|

W:170-900

L :170-900

W + L:340-1350

G:≤40

|

|

|

Overall dimension(L ×W ×H)

|

12.8×3.5×2.1m

|

14.2×4.2×2.3m

|

|

|

Machine power

|

18kW

|

||

|

Machine weight

|

约9.8t

|

约11.2t

|

|

Automatic glue spraying system,peristaltic pump glue spraying system

Multiple waste disposal system

Automatic strapping machine

Folding part

The brushes and high pressure blowers are adopted at the entrance to remove the wastes after die cutting and slotting;

Long span folding arm makes paperboard folding more smoothly,and more suitable for large paperboard;

90°squaring function effectively improve folding precision;

Speed of lower folding belts on both sides is independently adjustable,effectively correcting the fishtail;

Suction function of upper folding belt ensures stable cardboard conveying and make box forming more precise.

Gluing part

Glue wheel is driven by independent motor;

Glue box is flexibly floated and attached to glue wheel without leakage;

Use imported high quality diaphragm pump,durable in use.

Stacking Unit

Newly designed bottom-inserting stacking handles paperboard with high speed,stable without malfunction;

Air blower accelerates cardboard dropping,air volume and wind direction are adjustable;

Deep finishing and secondary flapping mechanism eliminates alignment error of cardboard,flapping frequency and number of times are adjustable;

Two-stage design of ejecting belt is more stable in cardboard ejection and counting stability.

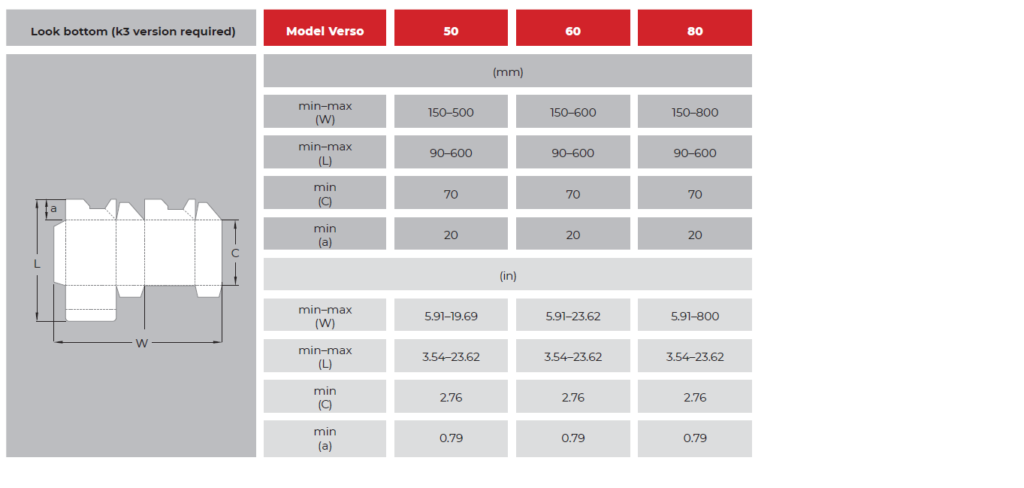

Rozměry produktů