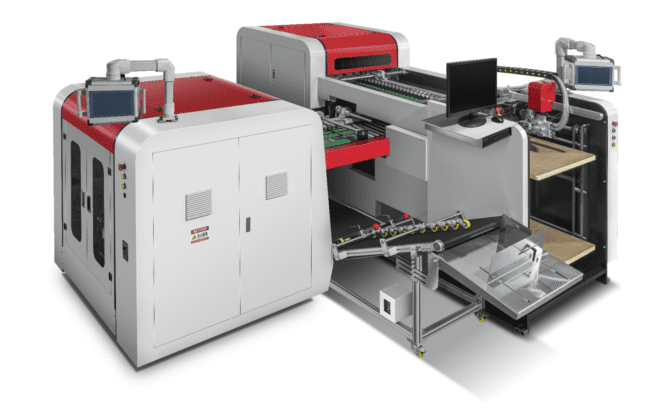

Flatbed Digital Cutter JWEI CB03II-1816RM with automatic loader

CB03II series intelligent flatted cutting solution for advertisement and packaging industry

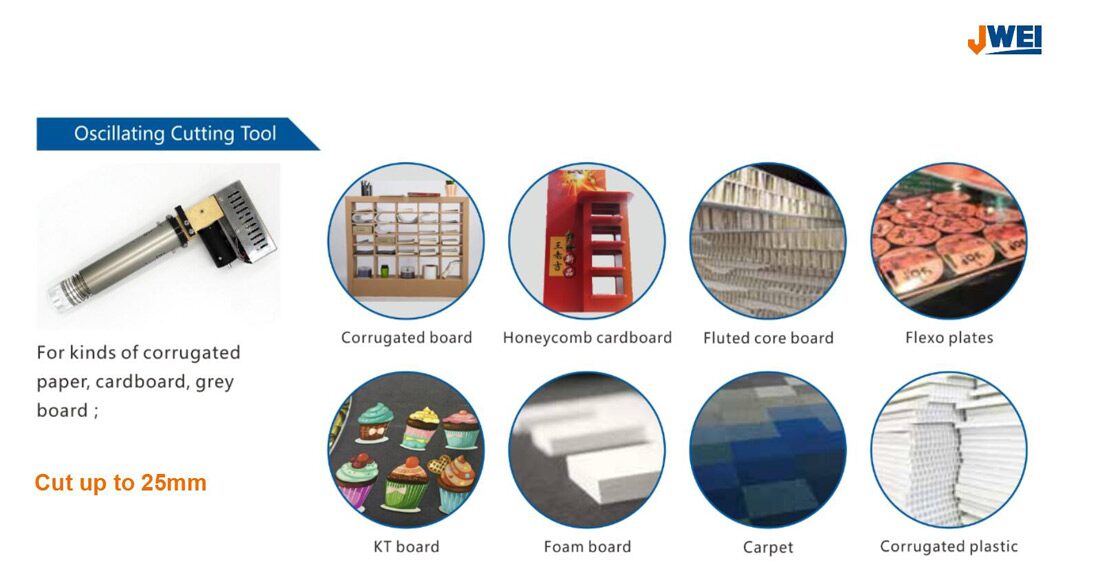

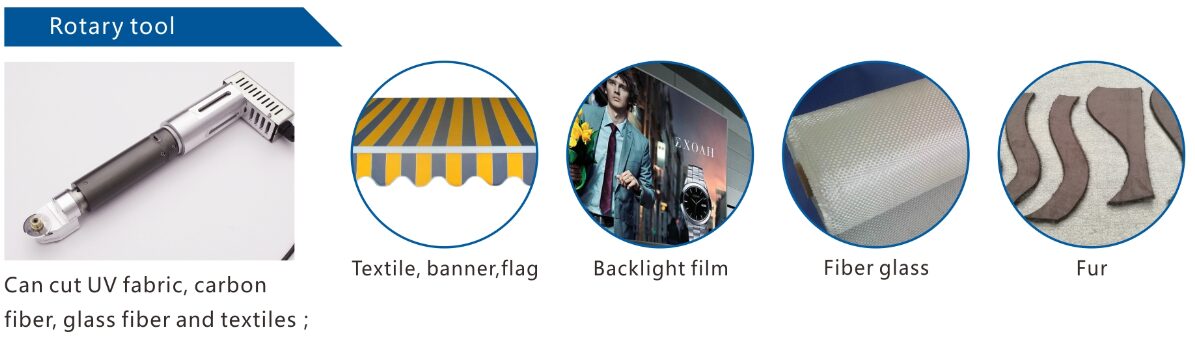

CB03II series flatted cutting machine is applicable to digital photo, spray painting, identification signs, props, display racks, special-shaped cutting etc.the cutting materials include all kinds of corrugated paper, grey cardboard, KT board, PVC expansion sheet, honey comb plate, light slide, PP gum, car sticker, flag fabric, EPE foam, foam, arcylic etc.

| Model No. | CB03II-2513-RM CB03II-2516-RM CB03II-1113 CB03II-1816-RM |

| Multifunctional head | Easy to change different tools. Engraving and router. Oscillating thorough cutting/ Kiss cutting/ Creasing/ Plotting/ Laser positioning, and precise camera registration. |

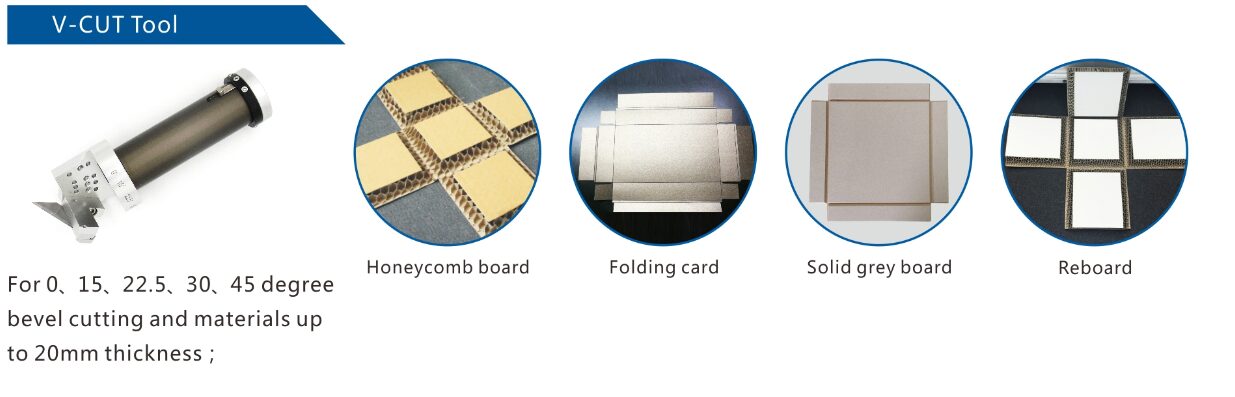

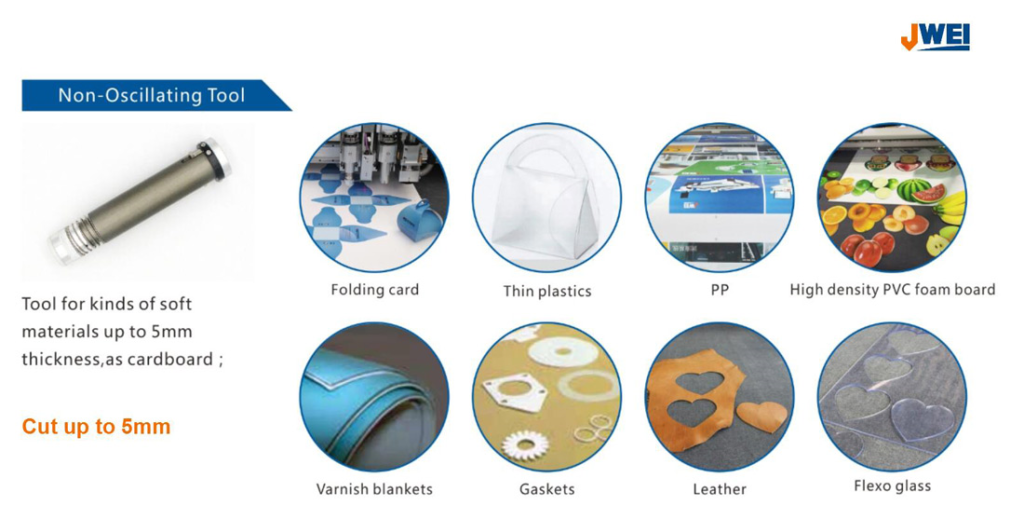

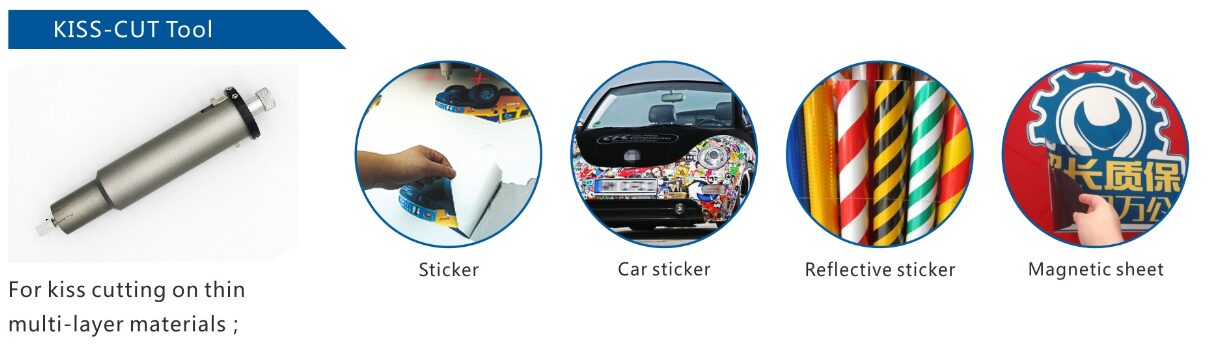

| Tools | Various kinds of cutting blades, different size of creasing wheels |

| Safety device | Infrared sensor, responsive, safe and reliable |

| Max. Speed | Up to 1500 mm/s |

| Cutting speed | Up to 1200 mm/s(Depends on different materials) |

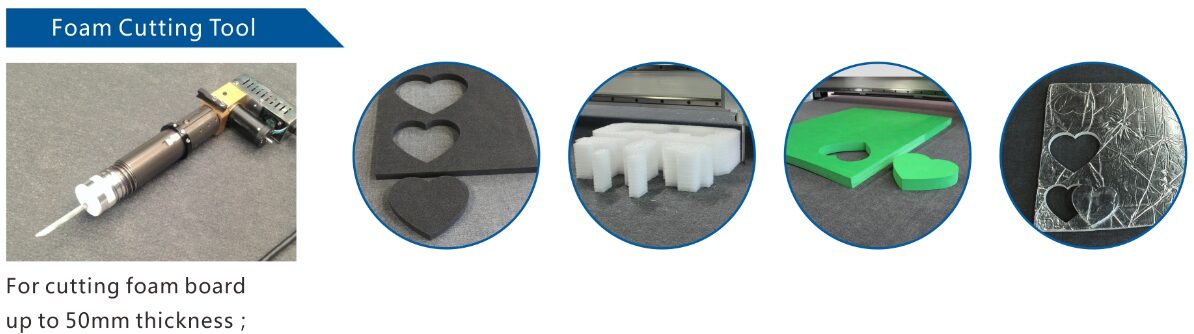

| Cutting thickness | Up to 50mm(Depends on different materials) |

| Cutting material | All kinds of corrugated paper, grey cardboard, KT board, PVC expansion sheet, honey comb plate, light slide, PP gum, car sticker, flag fabric, EPE foam, foam, arcylic etc. |

| Repeatability | Up to 0.05 mm |

| Repeat Precision | Up to 0.01 mm |

| Buffer memory | 2GB |

| Interface | Ethernet port |

| Work command | HP-GL compliant format |

| Transmission distance | Up to 350m |

| Transmission system | Digital servo driver, straight rail, synchronous belt, guide screw |

| Numerical control panel | EN LED Touch screen |

| Power Supply | AC 380V/220V±10% , 50HZ/60HZ |

| Working Environment | Temperature 0-35 degree; Humidity 60% – 80% |

| Effective Cutting Area | 2500mm*1300mm 2500mm*1600mm 1100mm*1300mm 1800mm*1600mm |

1. Multifunctional head,easy to change different tools. Engraving and router. Oscillating thorough cutting/ Kiss cutting/ Creasing/ Plotting/ Laser positioning, and precise camera registration.

2. CCD positioning cutting integrates positioning and task classification, which solves manual classification and recognition and ensures higher-precision cutting.

3. Equipped with automatic feeding and receiving system, it can realize unattended continuous work.

4. Higher cutting precision, especially for small shapes like small circle.

5. Upgrade of table and enhanced vacuum suction.

6. Integrated cable layout, One-whole head guard.