TB08II-3121-PM

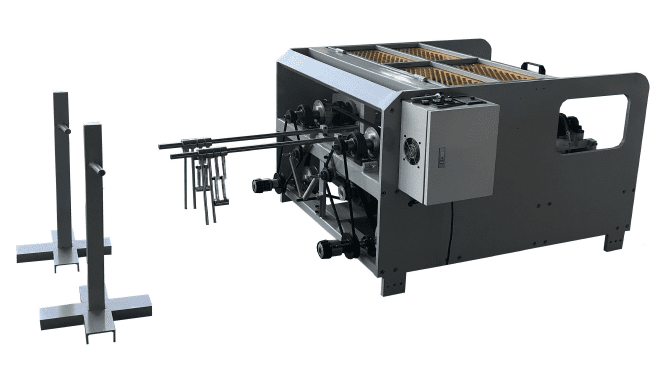

Framed by butt-end-joint industrial aluminum alloy profile, delivers high rigidness and base, easy for transporting and assembling, especially encounter with limit entrance.

Modularized cutting head with up to 3 sets of tools combinations.

Optional high power router assembly with vacuum cleaner system available: 1800w, max. 60,000RPM.

Optional Automatic Tool Changer (ATC) for routing, trimming and polishing rigid plate like acrylic, PVC foam board, MDF, ABS and various plastic board.

Carbon fiber reinforced gantry for intense industrial production, reliable and steady.

Separate vacuum areas for maximum holding-down force.

JWCS control software included as standard with friendly interface and powerful editing and optimizing functions.

| Model | TB08Ⅱ-3121-PM |

| Multi-functional | Easy to change different tools. Oscillating thorough cutting/ Kiss cutting/ Creasing/ Plotting/ Laser |

| machine head | positioning, and precise camera registration. |

| Tools | Various kinds of cutting blades, different size of creasing wheels. |

| Safety Device | Infrared sensor, responsive, safe and reliable. |

| Max. Speed | Up to 1500 mm/s |

| Cutting Speed | Up to 1200 mm/s(Depends on different materials) |

| Cutting Thickness | Up to 50mm(Depends on different materials) |

| Cutting Material | All kinds of corrugated paperboard, cardboard, Grey board, KT board, PVC expansion sheet, honeycomb |

| board, car sticker, light slide, PP gum, flex banner, Flag fabric, EPE foams, EVA, PVC plate, acrylic, thick foam etc. | |

| Repeat Precision | ≤0.05mm |

| Rated Power | 11KW |

| Material Fixing Method | Intelligent multi-sub-area vacuum absorption |

| Work Command | HP-GL compliant format |

| Numerical Control Panel | English-Chinese LCD Touch screen |

| Transmission System | Famous brand servo driver, high precise linear guide-way, gear and rack meshing transmission structure |

| Interface | Ethernet port |

| Power Supply | AC 380V ±10% |

| Effective Cutting Area | 3100mm×2100mm |

| Machine Size | 3970mmx2997mmx1450mm |