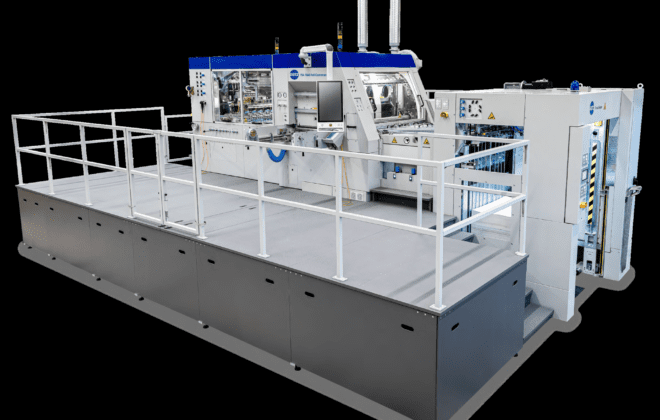

YOCO JY-76T automatic diecutting and foil stamping machine

- 3 units of Longitudinal foil feeding unit can handle maximum foil size 220mm in diameter, sufficient space for easy operation

- Adjustment of the pressing roller and foil feeding is very easy

- Maximum foil stamping speed is 6000 sheets per hour

- Servo motor from Japan Panasonic capable to handle pull foil in large area and at high speed

- Computerized control display system and touch screen operation can immediately trace and visualize machine status and possible machine stop causes.

- The servo motor of each roll can be controlled by PLC to set up for 3 different short pulls and long pulls

- Servo motor control pressure automatically, with special auto-drop pressure design when paper out or missing paper

- Ductile iron honeycomb chase and easy film holder for make ready

- 10 Individually controlled heating zones with tolerance ±1℃

- Foil roll diameter in 1 inch and 3 inch are available for selection

- Foil handle can be pulled out from machine, a user-friendly design to change new foil

- Air blowing foil separation device and dwell time device is available for big area stamping

- Residual foil length alarm is available

- Dwell time device is available for large area foiling.

- Pile tray with handle allowing manual lateral correction of the pile during production

- German design feeder with non-stop feeding supplied by MMS – Mabeg Machinery (Shanghai) Co.,Ltd

- Stream-wise feeding system with a highest speed of 120 sheets per minute

- 2 suction cups each for lifting paper, 2 suction cups for moving paper

- Height and angle of suction heads are easily adjustable

- Electronic safety devices preventing feeder pile from over ascending

- Micro-adjustment is available for transversal positioning of pile table

- Precision double-sheet detector

- Easy changeover of pull and push side guides simply by turning a bolt without the need of removing and replacing complete side guide

- 2 front guides with micro-adjustment and the side guide is adjustable by wheel handle

- Photo-electric detector with automatic stop system on feeding table in case of paper jam

- Separate drive controls of feeding unit and the main machine for easy make ready

- PLC and electronic cam for timing control

- The maximum diecutting pressure is 200 tons. The required pressure can be easily set up on touch screen, controlled by electrical pressure adjustment system. Digital display of pressure data facilitates set up of repeat jobs.

- Inverter- controlled main motor from SIEMENS contributes to maximum speed 7000 sheets /hour

- Computerized control display system and touch screen operation can immediately trace and visualize machine status and possible machine stop causes.

- Adopts automatic centralized lubricating system and automatic main drive chain

lubricating system.

- Centerlining system on diecutting chase ensures accurate registration and to shorten

changeover time. Options of 5mm plate and 4mm + 1mm plate are available for repeat runs.

- Reliable cutting chase turn-over device and centerline system to realize short set-up

time of repeat jobs

- Special designed 6 pieces aluminum gripper bar and positioning system, gripper plate 2-plate design.

- All main drive chains are tailored-made imported from Japan. Each chain has its own serial number and must undergo an intensive stretching process before ex-factory.

- Equipped with reliable brake air clutch imported from Europe

- Special designed upper heating function suitable for diecutting plastic material like OPP, PP,PE and PVC and so on

Embossing

- Emobssing function is available as standard

- The embossing plate will be installed onto the honeycomb plate , when paper pass through the diecutting unit, the embossing plate will meets the paper by pressure , then the embossing effect will be realized

Creasing

- The Creasing function is available as standard .

- Based on the paper’s thickness , the matrix with different width and height will be installed onto the die plate, when the paper enters into the die cutting unit and meets the die , the creasing effect will be realized.

- Non-stop delivery system with wooden paper supports

- Safety photo-electric devices preventing over-ascending and over-descending of delivery paper pile

- Adjustable depressor brush helps unloading paper from grippers and piling up paper

- Automatic auxiliary belt table available for non-stop delivery

- Feeder movement and speed control can be adjusted in the delivery unit

| Model | JY-76T |

| Maximum sheet size | 760×600mm |

| Minimum sheet size | 310×310mm |

| Maximum diecutting size | 750×580mm |

| Maximum stamping size | 750×530 mm |

| Minimum gripper margin | 8mm |

| Inside chase | 820×607mm |

| Sheet thickness | Cardboard 0.2-2mm |

| Corrugated board E、B | |

| Maximum diecutting pressure | 200tons |

| Heating zones | 10areas |

| Maximum speed | Diecutting 7000s/h |

| Stamping 6000s/h | |

| Maximum pile height at feeder | 1100mm |

| Maximum pile height at delivery | 850mm |

| Main motor power | 7.5KW |

| Electric hot plate | 20KW |

| Total power | Diecutting15KW |

| Stamping35KW | |

| Machine weight | 13Tons |

| Mahine size | 3610×3800×2200mm (including the footstep with chase changing table )

|

Categories