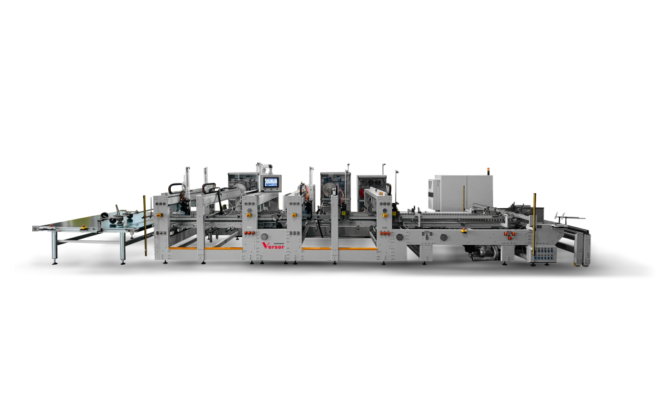

Tray Forming Gietz HTF 940

Inspired by decades of experience, the HTF machines for the forming and gluing of conical trays always result in outstanding customized solutions. With the Gietz HTF 940 we meet today’s growing customer requirements with a reliable, efficient and high output machine.

Gluing systems

The standard cold gluing unit applies dispersion glue on the blanks in the required shape by means of foam rubber pads on gluing wheels. Also available are high-pressure hot or cold glue spray systems.

Swing away delivery stack

The Gietz HTF machines are designed for a maximum operating comfort. Swing away delivery stacks allow optimal access to the forming stations, which enables a comfortable and quick set-up. The horizontal delivery of the completed trays simplifies the removal of erected trays at optimal height and with a minimum number of operators.

Fixed forming stations

Fixed forming stations are suitable for running repeat jobs due to the dramatically reduced setup time. Their pre-setting normally takes place at our production site in Gossau, Switzerland. Customers can also set them up on site, for which Gietz supplies the material.

Flanging Station

Enlarging the Gietz HTF 940 with a tray edge reinforcing station is quick and easy at any time. Fixed by hot glue, single or double folded reinforcement flanges are possible either on the inside or on the outside of the carton tray. This reinforces the trays for stronger resistance and better handiness.

1. Up to 12 000 pcs per hour

This highly productive machine can make up to 12,000 pieces per hour.

2. Modularly retrofittable machine

The HTF can be retrofitted with additional options. For example, a station for bending the top edges of boxes or plasma nozzles for finishing coated sheets.

3. High production safety in the loading unit

Pneumatically controlled sheet loading ensures the highest reliability and production safety.

4. Choice of gluing system

Whether 2/4/6 or 8 point gluing is required, HTF offers customers a complete choice of gluing system. The machine can be equipped with both dispersion and hot-melt gluing units.

5. Intelligent movement of the forming hoof

The HTF can be retrofitted with additional options. For example, stations for bending the top edges of boxes or plasma nozzles for finishing coated sheets.

6. User-friendly

The swing-out device allows easy access, quick and convenient adjustment of the forming stations. Horizontal unloading of conical boxes at the optimum working height simplifies removal of finished products during production.

7. Short setup time

A special moulding set can be prepared for all boxes, which saves very considerable time for re-setting orders. Each of these moulding kits is manufactured in-house by Gietz to fully meet the customer’s requirements.

8. High reliability and durability

From 1968, Gietz has been manufacturing machines for the creation of conical boxes. This know-how, together with practical experience from hundreds of users, is implemented in the design of the HTF machine. In addition, the machine’s very solid and robust construction guarantees a long service life.

9. Price/performance ratio

Highest quality of moulding and gluing systems. Maximum production speed, as well as a high-quality durable construction – all this is Gietz.

10. Top product for professionals

Gietz conical box forming and gluing machines are recognized by the printing industry worldwide as the leading expert for professionals in their field.